Introduction:

In the intricate world of industrial machinery, gears play a pivotal role in ensuring seamless and efficient operations. The production of industrial gears involves a meticulous process, with gear hobbing and cutting standing out as essential techniques. In this article, we delve into the fascinating realm of gear manufacturing, shedding light on the intricate processes involved in wheel gear making and cutting.

Understanding Gear Hobbing:

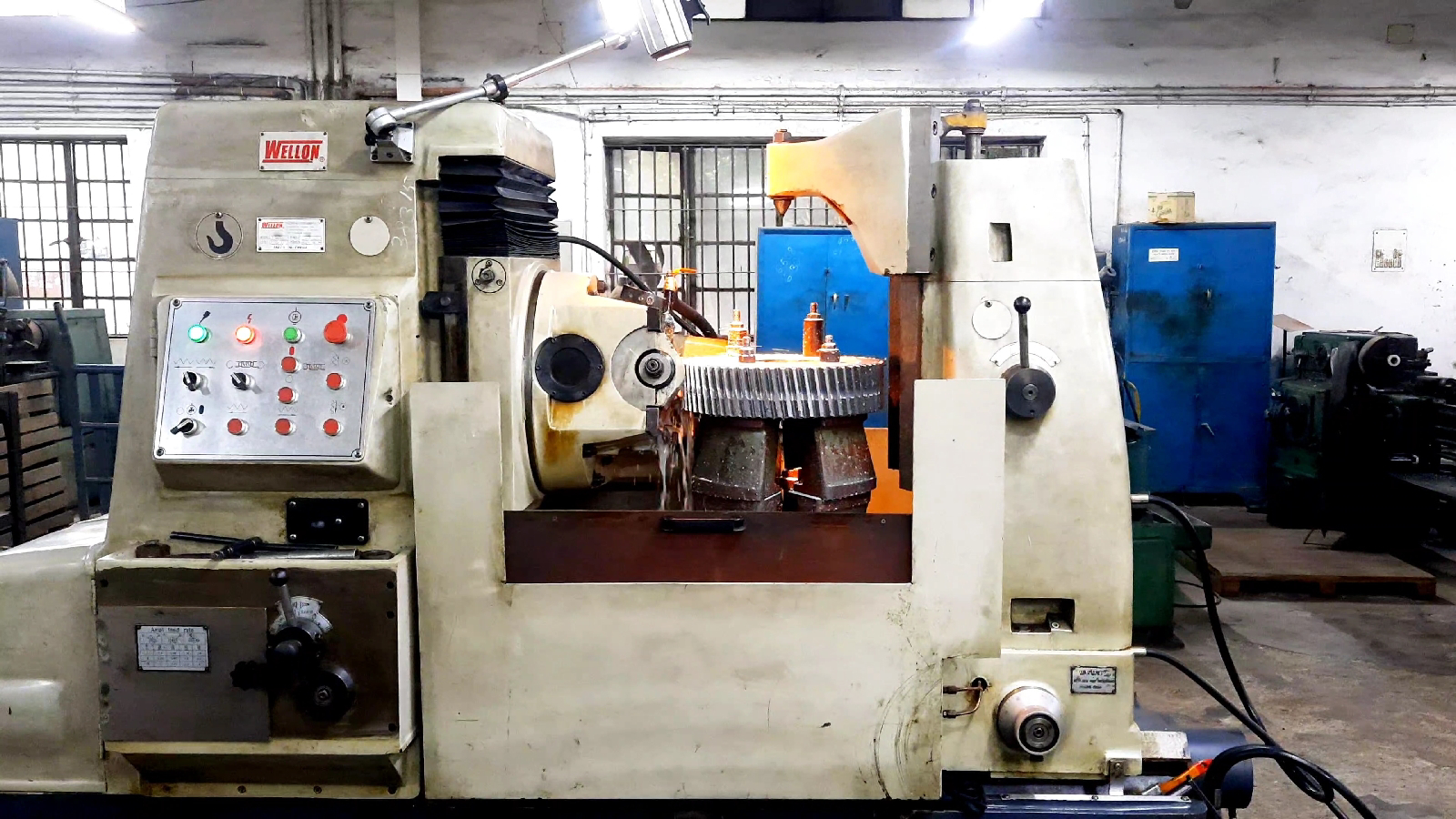

Gear hobbing is a precision machining process used for creating gears, sprockets, and splines. The heart of the gear hobbing process lies in a specialized tool called a hob, which resembles a worm gear with cutting edges. During hobbing, the workpiece is rotated while the hob is gradually fed into it, generating the desired gear profile. This process ensures accuracy, repeatability, and efficiency in the production of gears for various industrial applications.

Key Steps in Gear Hobbing:

1. Material Selection: The first step in gear hobbing is selecting the appropriate material for the gear. Common materials include alloy steels, stainless steels, and cast irons, chosen based on factors such as load-bearing capacity, durability, and application requirements.

2. Blank Preparation: The selected material is cut into a blank, a rough form that will be shaped into the final gear during the hobbing process.

3. Mounting the Workpiece: The gear blank is securely mounted onto a hobbing machine, where it undergoes precision rotations for accurate hobbing.

4. Hobbing Operation: The hob is carefully aligned with the workpiece, and the cutting process begins. The hob gradually cuts into the blank, creating the intricate tooth profiles of the gear.

5. Finishing Touches: After the initial hobbing operation, additional processes such as gear shaving and grinding may be employed to achieve the desired surface finish and dimensional accuracy.

Wheel Gear Cutting Process:

Wheel gear cutting is a complementary process that focuses on shaping gears through the removal of excess material. This method is often used to refine the gear's teeth and achieve specific geometrical characteristics.

Key Steps in Wheel Gear Cutting:1. Gear Blank Preparation: Similar to gear hobbing, the process starts with selecting a suitable material and preparing a gear blank.

2. Mounting the Gear Blank: The gear blank is mounted onto a cutting machine, and precise adjustments are made to ensure proper alignment.

3. Cutting Operation: The cutting machine, equipped with specialized cutting tools, removes excess material from the gear blank to create the final gear shape.

4. Quality Control: Throughout the cutting process, quality control measures are implemented to ensure the gear meets the required specifications and tolerances.

Conclusion:

The production of industrial gears through gear hobbing and cutting processes is a sophisticated art that combines precision engineering with technological innovation. As industries continue to demand higher performance and efficiency from machinery, understanding these gear manufacturing processes becomes increasingly crucial. By unraveling the intricacies of gear hobbing and cutting, manufacturers can elevate the quality and reliability of industrial gears, contributing to the seamless functioning of diverse machinery across various sectors.

Comments

Post a Comment